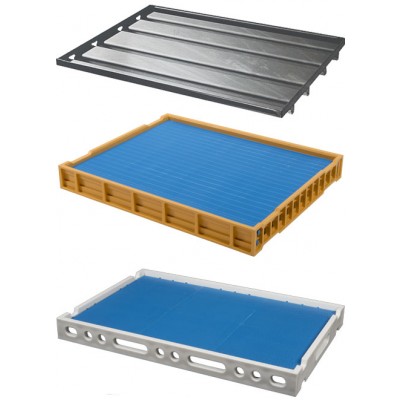

Moulding, Draining and Demoulding

The moulding step is essential in defining the weight and shape of your finished cheese. It can be simplified by the use of tools such as a container turner or a mould distributer, essential for consistency in the finished product.

The curd is then separated from the whey during the draining process.

Turning the cheeses to optimise draining can be facilitated by the use of a draining table for recovering the whey, or by using stack turners.

Photo taken at : Fromagerie de la Mothe Saint-Héray